Guida per la valutazione del colore dell'armadio GT-D08

Nell'industria tessile, la consistenza del colore è sempre stato uno dei fattori più difficili da controllare, ma è anche uno degli elementi chiave che maggiormente incidono sulla qualità finale.

Mobiletto coordinato nei colori

: I colori appaiono in modo diverso a seconda delle fonti di illuminazione. Per evitare/ridurre l'errore di valutazione durante l'esecuzione del contrasto cromatico, possiamo utilizzare una cabina di illuminazione/cabina di visualizzazione/scatola luminosa per simulare diverse fonti di luce e ottenere una valutazione oggettiva del colore e delle differenze cromatiche, sempre e ovunque.

I. L'importanza del gabinetto di valutazione del colore

Cominciamo con l'esempio più semplice della vita quotidiana: quando andiamo in un negozio per comprare vestiti, l'illuminazione particolare del negozio spesso rende un capo molto bello, spingendoci ad acquistarlo. Tuttavia, quando lo indossiamo all'aperto o torniamo a casa, l'impressione visiva diminuisce notevolmente e potremmo persino avere la sensazione che il colore non sia abbinato e rifiutarci di indossarlo di nuovo. Il motivo è che sotto diverse fonti di illuminazione, l'occhio umano percepisce il colore dello stesso oggetto in modo diverso, il cosiddetto effetto metamerismo.

Il metamerismo è un problema comune nel settore tessile a causa di fattori tra cui:

Diverse sorgenti luminose hanno composizioni spettrali diverse, che influenzano la percezione umana dei colori;

Anche piccole differenze nelle formulazioni dei coloranti possono dare origine a risultati visivi diversi in base all'illuminazione;

Un controllo instabile della tintura tra i lotti di produzione aumenta ulteriormente il rischio di deviazione del colore;

La luce naturale non può rimanere stabile a lungo e i cambiamenti meteorologici e orari possono influenzare i risultati del confronto.

Per questi motivi, gli ambienti professionali devono utilizzare apparecchiature in grado di simulare più sorgenti luminose, garantendo al contempo la stabilità a lungo termine dell'ambiente di osservazione del colore: una light box per la corrispondenza dei colori. Questa elimina l'influenza delle condizioni esterne, consentendo valutazioni cromatiche coerenti in momenti, personale e luoghi diversi, garantendo così la stabilità del controllo qualità.

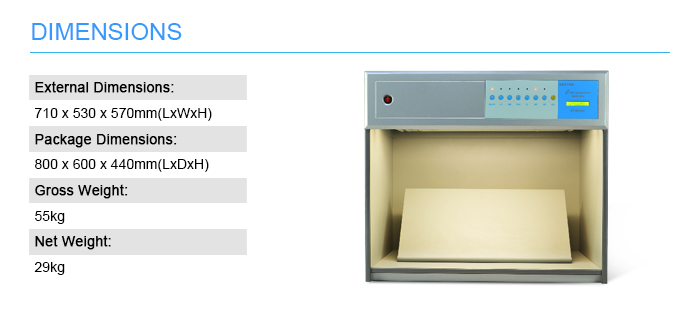

II. Caratteristiche del cabinet per la valutazione del colore GT-D08

Le cabine per la valutazione del colore riproducono il colore in modo più accurato. Grazie a 6 diverse sorgenti luminose (D65, TL84, CWF, F, UV, U30), possono rilevare il metamerismo.

|

Fonte di luce

|

Visualizzazione del colore

B

denti A

pp

licazione

|

Colore tem

P

era

T

ure(K)

|

Potenza (W)

|

|

D65

|

Standard internazionali di luce diurna artificiale

|

6500

|

18

|

|

TL84

|

Applicato ai negozi in Europa, Giappone e Cina

|

4000

|

18

|

|

CWF

|

(Coll White Fluorescent) Standard americano

|

4150

|

18

|

|

F

|

Sorgente luminosa a incandescenza “Sun-Setting Light Yellow” (imitazione del tramonto)

|

2700

|

40

|

|

UN

|

Riflettori puntati su American Standard

|

2856

|

60

|

|

UV

|

Visualizzazione sotto luce ultravioletta per rilevare e valutare sbiancanti ottici o pigmenti fluorescenti

|

Lunghezza d'onda: 365 nm

|

20

|

|

U30

|

Fluorescente bianco caldo, standard americano

|

3000

|

18

|

La combinazione di più sorgenti luminose simula vari scenari applicativi reali, dalla luce naturale all'illuminazione dei negozi fino agli ambienti domestici, consentendo di rilevare se i materiali presentano metamerismo e migliorando la precisione della valutazione.

Scatola luminosa con abbinamento di colori

: Soddisfa o supera i principali standard internazionali per la valutazione visiva del colore, tra cui ASTM D1729, ISO 3664, DIN, ANSI e BSI.

Facile da usare grazie agli interruttori individuali per ogni sorgente luminosa.

Misuratore del tempo trascorso per monitorare la sostituzione ottimale della lampada.

Le sorgenti luminose sono disponibili per alternarsi.

Nessun tempo di riscaldamento né sfarfallio, il che garantisce una valutazione rapida e affidabile del colore.

Consumo energetico ridotto e bassa generazione di calore per un'elevata efficienza luminosa.

III. Light box per metodo operativo tessile

La selezione delle diverse sorgenti luminose nel Light Box per tessuti è controllata tramite i pulsanti touch corrispondenti ai nomi delle sorgenti luminose sul cabinet, consentendo una rapida commutazione e attivazione. Posizionare i due oggetti di cui si desidera confrontare la deviazione del colore in posizioni simmetriche al centro del cabinet. L'angolo di osservazione ottimale è di 45 gradi, a condizione che l'occhio umano o la luce e l'oggetto testato siano entrambi a 45 gradi.

IL

Scatola luminosa GT-D08

È anche possibile registrare il tempo di utilizzo di ciascuna lampada. Dopo che una lampada è stata utilizzata per più di 2000 ore, deve essere sostituita con una nuova per evitare effetti di invecchiamento che potrebbero influenzare l'osservazione visiva del colore.

IV. Settori applicativi

Le apparecchiature per la corrispondenza del colore sono utilizzate principalmente nella gestione del colore in quattro settori principali: tessile, abbigliamento e tintura; plastica e prodotti elettronici; vernici e inchiostri; stampa e produzione di carta. Trovano impiego anche in settori emergenti come l'ispezione con telecamere, la fotografia e gli strumenti di laboratorio per istituti scolastici.

V. Manutenzione

Se i pannelli delle pareti interne della lampada UV D65 TL84 sono macchiati, pulirli con un panno morbido e pulito imbevuto di un detergente alcalino a bassa concentrazione. Mantenere il telaio interno pulito e asciutto per evitare di danneggiare il rivestimento assorbente della parete interna con gli oggetti di prova, compromettendo le prestazioni di corrispondenza dei colori.

Se il pannello interno è danneggiato e non riesce più ad assorbire efficacemente la luce, è necessario sostituirlo. Anche le lampade devono essere sostituite quando superano il loro periodo di utilizzo e presentano annerimento e invecchiamento su entrambe le estremità.